TRADE GET 10% OFF - SIGN UP HERE

What is COB LED Strip Light?

What is COB Continuous LED Strip Light?

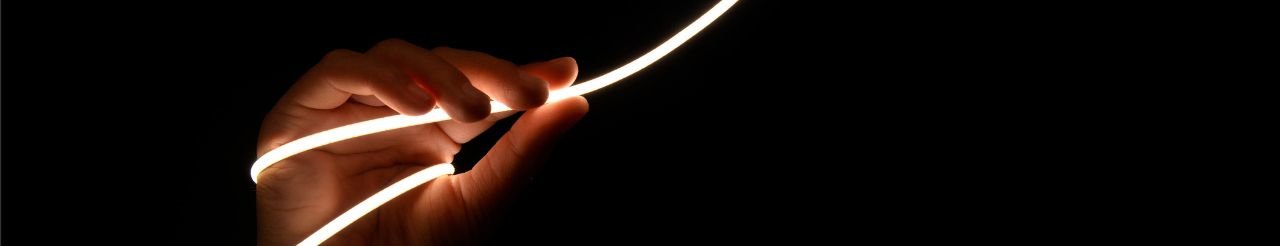

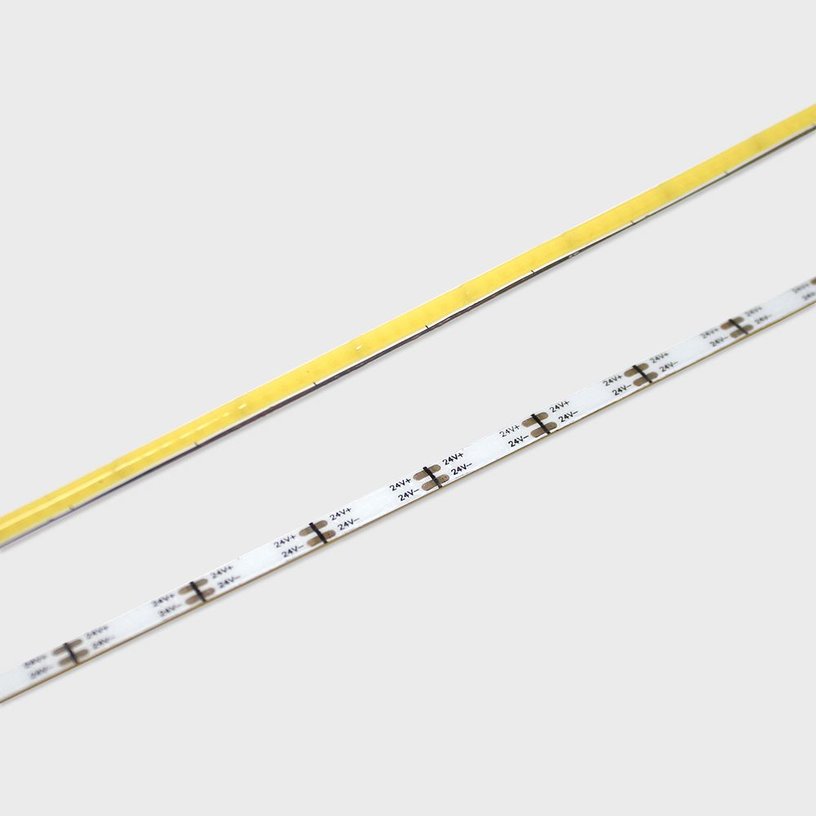

COB stands for Chip on Board, meaning the LED diodes are built directly into the printed circuit board. A phospur coating is then applied over the LED chips and acts as built-in diffuser. The main advantage of this technology is that there is no visible spotting, even when used in more shallow LED profiles and spaces, this ensures the finished installation will present a seamless uninterrupted finish.

This makes our COB Continuous LED Strip Light perfect for high-end professional and commercial installations. The high build quality and components will assure long lasting performance and reliability.

What makes COB LED Strip Light different to standard LED Strip Light?

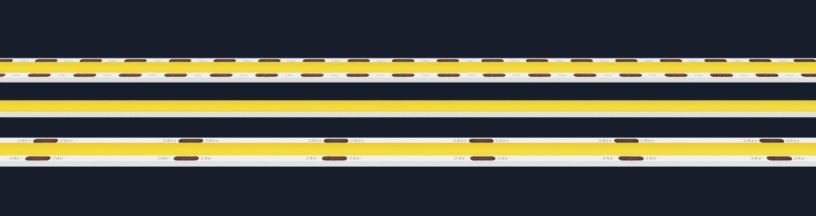

COB LEDs are mounted directly into the circuit board with a cover of phospur over the top acting as a ‘diffuser’ enabling a seamless finish when illuminated. Being directly mounted to the circuit board means there is room for more LEDs to be mounted. Our COB LED strip lights typically achieve between 320-544 LEDs per metre.

Compare this to current traditional LED strip light and the use of SMD (Surface Mounted Diode) technology, where the LED chips are mounted and secured on top of the circuit board. This manufacturing process typically achieves a maximum of 240 LEDs per metre.

The SMD version is much more likely to cause spotting and dark spots due to the spacing of the chips on the LED strip light. This spotting effect can be emphasised when the strip light is installed into a shallow LED profile with a semi clear, or transparent diffuser.

COB LED strip light on the other hand produces no spotting and can even be used without an LED profile.

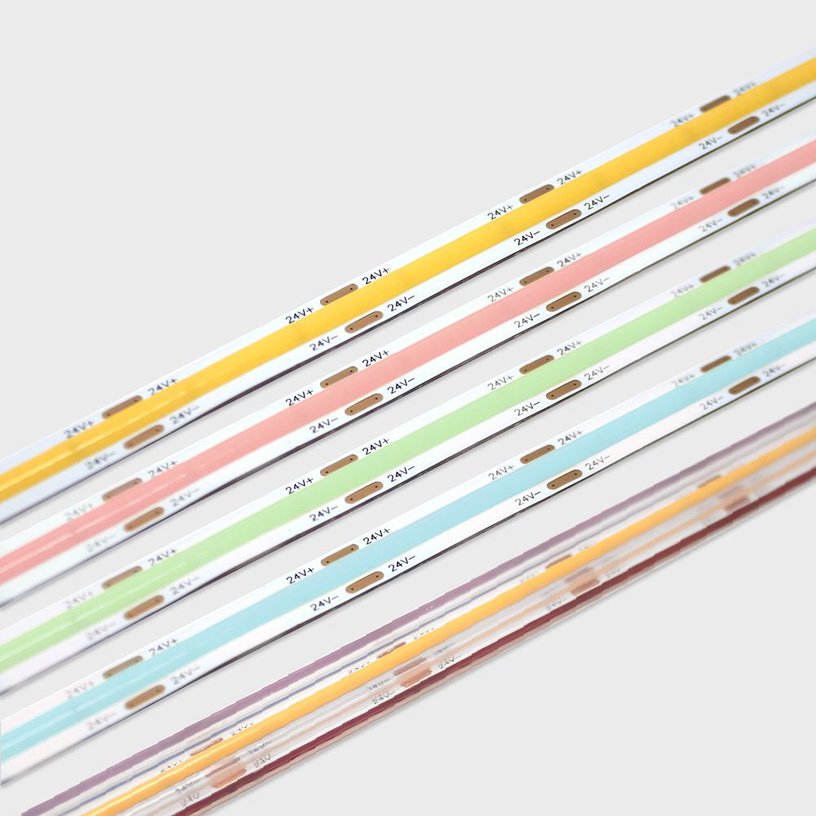

Our current range of COB LED strip lights:

EC24 Essential COB - 50M Reels

- Available in 50 metre reels.

- IP20 rating - perfect for indoor use.

- Available is colour temperatures 2700K, 3000K, 4000K & 6500K.

- 24V, 8W per metre, 50mm cut points, 320 LEDs per metre

- 3 Year Warranty

PC24 Professional COB - 5M/50M/IP67 Reels

- Available in 5 metre & 50 metre reels.

- IP20 rating - perfect for indoor use.

- IP67 rating - water resistant.

- Available is colour temperatures 2700K, 3000K, 4000K, 6500K, Red, Green & Blue.

- 24V, 11.2W per metre, 29.41mm cut points, 544 LEDs per metre

- 5 Year Warranty

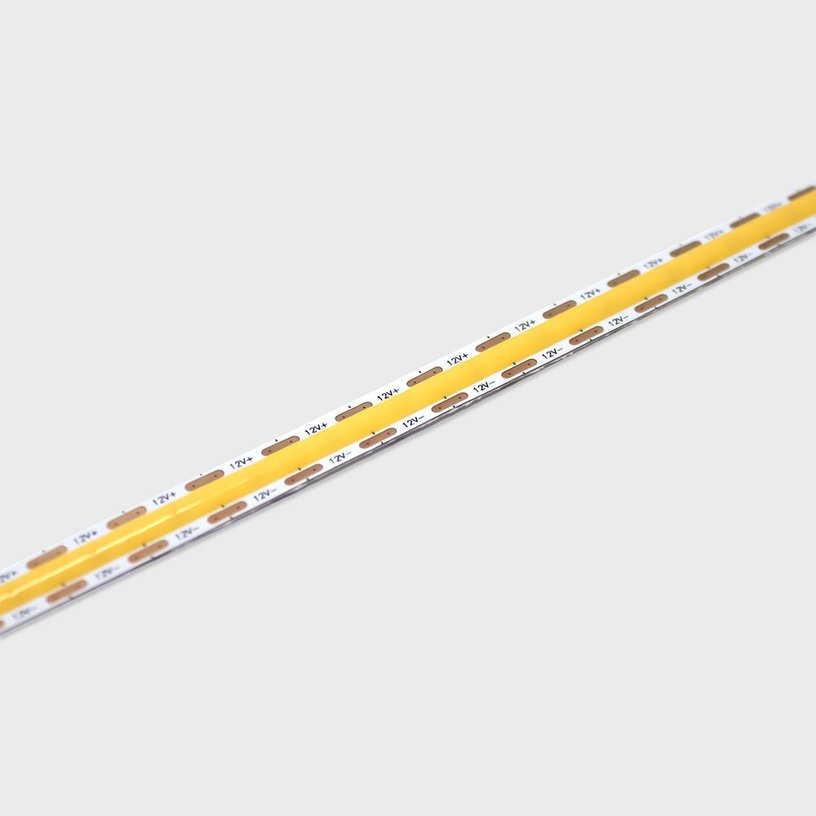

PC12 Mini Cut Professional COB - 2.5M Reels

- Available in 2.5 metre reels.

- IP20 rating - perfect for indoor use.

- Available is colour temperatures 2700K, 3000K, 4000K & 6500K.

- 12V, 9W per metre, 10mm cut points, 400 LEDs per metre

- 5 Year Warranty

PC24 Micro Width Professional COB - 2.5M Reels

- Available in 2.5 metre reels.

- Micro Width of 4mm.

- IP20 rating - perfect for indoor use.

- Available is colour temperatures 2700K, 3000K, 4000K & 6500K.

- 24V, 10W per metre, 16.67mm cut points, 420 LEDs per metre

- 5 Year Warranty

TP24 RGB Professional COB - 5M Reels

- Available in 5 metre reels.

- IP20 rating - perfect for indoor use.

- Available in colour changing RGB.

- 24V, 16.8W per metre, 25mm cut points, 840 LEDs per metre

- 3 Year Warranty

TP24 RGB+W Professional COB - 5M Reels

- Available in 5 metre reels.

- IP20 rating - perfect for indoor use.

- Available in colour changing RGB+300K & RGB+6000K.

- 24V, 19.2W per metre, 33.33mm cut points, 840 LEDs per metre

- 3 Year Warranty

TP24 CCT Professional COB - 5M Reels

- Available in 5 metre reels.

- IP20 rating - perfect for indoor use.

- Available in colour changing CCT (2700K~6000K)

- 24V, 9.6W per metre, 27.78mm cut points, 576 LEDs per metre

- 3 Year Warranty

TD24 Digital Pixel COB - 5M Reels

- Available in 5 metre reels.

- 30 pixels per metre, TM1903 IC type.

- IP20 rating - perfect for indoor use.

- Available in colour changing digital pixel.

- 24V, 32.5W per metre, 33.33mm cut points, 720 LEDs per metre

- 2 Year Warranty